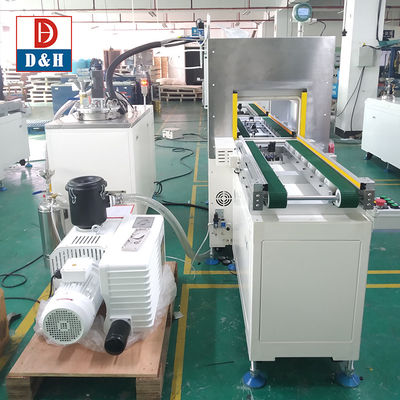

1.1 Product feed in and out automatically

1.2 Glue preprocessing (tank stir , tank bubble degas , heating , Tank filter , vacuum degas)

1.3 Glue ratio and quantify mixture .

1.4 Glue filling evenly .

1.5 Through programming to realize glue potting for different products sizes .

1.6 Fully automatic weigh system to re-inspect the glue amount for each product .

1.7 Set fixed time to let glue discharge and prevent glue mixture curing inside the tube .

1.8 Autumatically clean the mixing part of the machine.

1.9Transmit data on MES system .

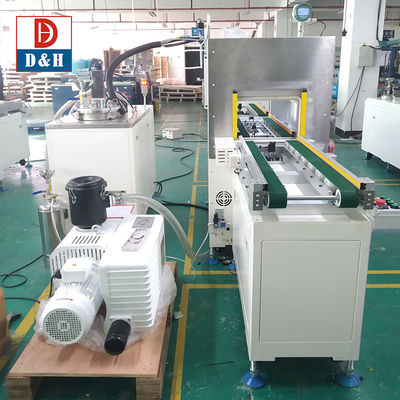

1.2 Glue preprocessing (tank stir , tank bubble degas , heating , Tank filter , vacuum degas)

1.3 Glue ratio and quantify mixture .

1.4 Glue filling evenly .

1.5 Through programming to realize glue potting for different products sizes .

1.6 Fully automatic weigh system to re-inspect the glue amount for each product .

1.7 Set fixed time to let glue discharge and prevent glue mixture curing inside the tube .

1.8 Autumatically clean the mixing part of the machine.

1.9Transmit data on MES system .