All Products

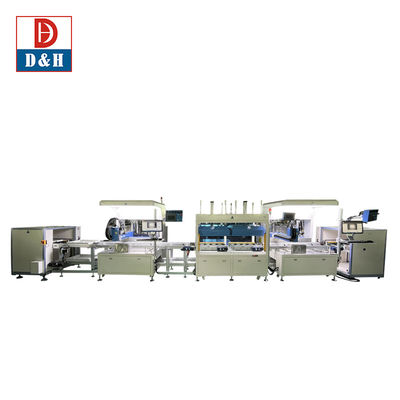

Polywood Case Packaging Material Epoxy Moulding Machine with Automatic Feeding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Type | Gluing Machine | Applicable Industries | Manufacturing Plant |

|---|---|---|---|

| Showroom Location | Turkey, Italy, Viet Nam, Indonesia, Russia, Thailand, Malaysia | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Warranty Of Core Components | 1 Year |

| Core Components | PLC, Pump | Condition | New |

| Application | PU,epoxies ,silicone | Packaging Type | Polywood Case |

| Packaging Material | Plastic, Polywood Case | Automatic Grade | Automatic |

| Driven Type | Electric | Voltage | 220V /380V |

| Weight | 500 KG | Warranty | 1 Year |

| Key Selling Points | High Productivity | Keywords | Epoxy Moulding Machine Epoxy Moulding Machine Machine Leveling Epoxy |

| Feeding Way | Automatic Feeding | Function | Vacuum , Heat , Stir , Self-clean |

| Mixing Way | Dynamic /static Mixing | Tank Compacity | 10L,25L , 40L Or Customized |

| Precision | ±2% | Glue-out Precision | 0.5-12g/s |

| Speed | 0-300mm/s | Pump Precision | 0.2g/s |

| Control System | PLC Programming |

Product Description

Why Choose Us

Epoxy moulding machine epoxy moulding machine machine leveling epoxy

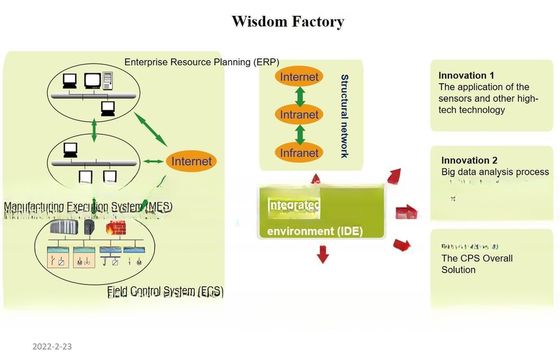

We Daheng Automation specialize in different types of potting and dispensing system. No matter what your resin application requirements look like: we can do most of them in our fully equipped lab. We can handle 1- and 2-component polyurethanes, epoxies, acrylics, silicones, temperature, humidity and UV curing materials. They can be from low- to high-viscosity, filled or unfilled and even high abrasive for thermal conductivity.

Potting is the process of embedding products & assemblies in a liquid resin (potting compounds) to protect them against rough environment conditions. Potting can be performed in atmosphere pressure or even under vacuum, if high voltage insulation and high temperature differences are needed.

We offer automatic ,se-mi automatic fluid dispensing potting machine and the related production line and vacuuming systems .

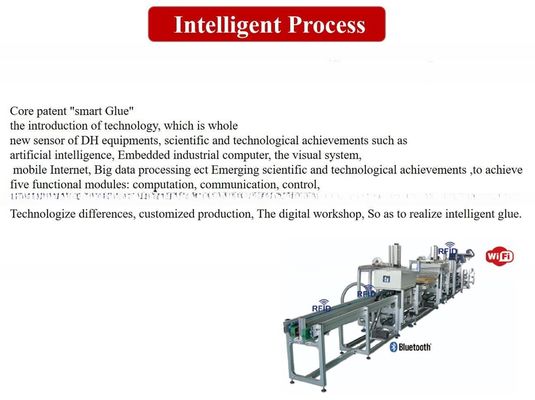

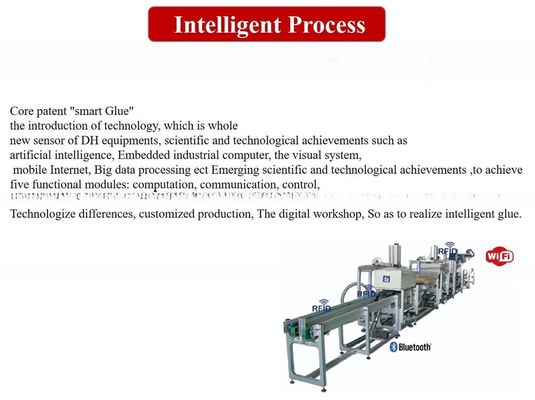

Introduction :

1. Working Area: controlled by PLC module and MCGS touch screen. 2.High precision valve: high speed, glue off clean, no glue drawing, no dropping. 3. Gear pump special for transparent glue. 4. Mix glue A & B more evenly; no more or no less for agent B.

Working principle :

Compound materials A & B are kept in two tanks separately. There are two sets of metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data.

Tank system technology:

1. Stainless panel vacuum pressure tank which can bear negative pressure of inner tank . 2. Tank with motor stirrer that prevent the glue from sediment and keep the potting material in constant temperature. 3 Tank with top/ high /low liquid sensors that ensure alarm warning when liquid higher or lower the setting level . 4 Tank with vacuum degas (degas time can be set through touch screen), so the material can be re-feeding through vacuum negative pressure . 5 Tank with pressure releasing ball valve ; the bottom of tank reserved back-flow connector and river closure ball valve. 6 Tank with artificial feeding mouth that can be added glue appropriately by hand . 7 Tank with silica-dryer which can prevent material especially PU from crystallization .

D&H Pump technology

1. Two cylinder plunger pumps work by durable motors. 2.The biggest flow volume :24g/s,Repetition accuracy:0.2g. 3.Also Suitable for high viscosity glue: 50cps~35000cps. 4. Suitable for big flow dispensing or slight flow dispensing. 5. Suitable for frequent start and stop dispensing. 6. Anti-wear, Anti-corrosion, super long life time.

Valve technology

1. Two cylinder plunger pumps work by durable motors. 2.The biggest flow volume :24g/s,Repetition accuracy:0.2g. 3.Also Suitable for high viscosity glue: 50cps~35000cps. 4. Suitable for big flow dispensing or slight flow dispensing. 5. Suitable for frequent start and stop dispensing. 6. Anti-wear, Anti-corrosion, super long life time.

Tech Data

Glue ratio | 100:100—100:10 or customized |

Machine area | 600(X)*400(Y)*100mm(Z) |

Working path | Dot, line, curve, circle |

Visual system | CCD visual capture and positioning |

Positioning way | Visual capture positioning system software |

Production line function | Screw+Servo |

Speed | 500mm/s (displacement speed) 1-12ml/s (single pump glue speed) |

Accuracy | ±0.03 (±0.1) mm (repeat positioning accuracy) ±2% (glue potting) ±2% (glue dispensing) |

program inventory | 999pcs |

input air pressure | 0.3MPa—0.75MPa |

glue viscosity | 50cps~35000cps |

flow control | PLC/Dual Cylinder Piston Pump |

Programmatically | digital input |

Automation Control System | PC programming |

Mixed way | Dynamic mixing, instant mixing, easy cleaning |

Reservoir system | Stainless steel barrel (60L), (40L) |

main power | 220V/50Hz/1.5kW (without heating) |

Line height | 850-950 (can be customized) |

Line width | Maximum 550mm (visual 400mm) (actual customization shall prevail) |

conveyor line | Chain drive |

Targeting | Clamping and positioning |

Blocking Cylinder Arrangement | Three by default |

Glue method | A glue diaphragm pump glue function |

PLC Operation Controlling System

1 Dispensing volume is controlled by the speed of pump’s motors ; Glue speed adjustable within the speed range .

2 Machine with detecting function that detect the speed and running time of pumps to ensure the ratio reliability.

3 Adjustable gluing-out volume make sure glue A/B dispense out at the same time from glue valve to get better glue mixing effect .

4 Machine with gel resistance calculator , which prevent the mixture curing inside .

5 You can set single gluing-out and steady gluing-out function to meet up with your different process requirement .

6 Whole machine system and function is controlled by Panasonic PLC and MGCS touch screen .

7 Reserved PLC communication interface, which easy connecting with outside device .

8 Equipped with a safety lock to prevent staff from wrong operation .

Parameter | Category | Specification | |

Mixing ratio | 1:1—10:1 | Speed | 0-300mm/s(displacement speed) |

Working area | Inner area:600x400x100mm | ||

Program memory | 999 pcs | Precision | ±0.1mm (accuracy of displacement)±2%(mixing accuracy) |

Input air pressure | 0.3MPa—0.75MPa | ||

Viscosity range | 50cps~35000cps | Working path | Dot, line , arc , circle |

Operation mode | JOG/AUTO | ||

Control system | PLC | Auto control system | Industrial touch screen program with programming modification, storage and so on |

Flow control | Digital input | ||

Programming method | Teaching programming | Out-glue control system | AB glue suck-back valve /vacuum suck back skill. |

Mixing mode | Dynamic | ||

Power | 380V/50Hz/1200W | Storage system | Stainless steel tanks A Tank: 40L & B Tank: 25L(10L,25L ,40L optional) |

Vacuum degree | -0.1MPa | Vacuum time | as per different requirement |

Application

1.Potting &Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reverse sensor, circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts.... 2.Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling .... 3.Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

Applicable material

1K and 2-component polyurethanes, epoxies, acrylics, silicones, temperature, humidity and UV curing materials. Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .

Service Term

1、 Staff training Seller is responsible to provide machine’s training including installation, debugging, maintenance to assured customer can totally use the operation skills and well acknowledge maintenance of machine .

2、Maintenance Service 2.1Seller provide one year warranty period and support free maintenance service during warranty . Software upgrade service is provided for a long life time.

2.2 In case parts of the machine become broken within the warranty because of non-artificial factors, we send you part replacement free, buyer pay for the shipment. Double-liquid valve should be bought at its cost price.

2.3If the parts of the machine become broken past warranty , the parts replacement should be shouldered by buyer.

FAQ

Q:Do you offer oversea service? A:We have overseas service center in some countries, we can support local service as per discussion. And we also can offer oversea service if customer required, engineer will offer face to face service. | ||||||||

Q:How dose your factory do regarding quality control? A:We assure 1 year warranty for the main part,also we offer spare part for back up. Please check with sales engineer in detail. | ||||||||

Q:What are your payment terms? A:Normally, 30% advance by T/T and balance paid off before delivery. | ||||||||

Q:Are you a factory or trading company ? A:We are a factory with SGS certified and more than 30 patents,and cooperate with different customers coverd about 50 countries for over 19 years. | ||||||||

Recommended Products