All Products

Packaging Type Polywood Case Epoxy Resin Dispensing Potting Robot for 500 KG Capacity

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Type | Gluing Machine | Applicable Industries | Manufacturing Plant |

|---|---|---|---|

| Showroom Location | Turkey, Italy, Viet Nam, Indonesia, Russia, Thailand, Malaysia | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Warranty Of Core Components | 1 Year |

| Core Components | PLC, Pump | Condition | New |

| Application | PU,epoxies ,silicone | Packaging Type | Polywood Case |

| Packaging Material | Plastic, Polywood Case | Automatic Grade | Automatic |

| Driven Type | Electric | Voltage | 220V /380V |

| Weight | 500 KG | Warranty | 1 Year |

| Key Selling Points | High Productivity | Definition | Polyurethane Epoxy Silicone Potting Machine |

| Feeding Way | Automatic Feeding | Function | Vacuum , Heat , Stir , Self-clean |

| Mixing Way | Dynamic /static Mixing | Tank Compacity | 10L,25L , 40L Or Customized |

| Precision | ±2% | Glue-out Precision | 0.5-12g/s |

| Speed | 0-300mm/s | Pump Precision | 0.2g/s |

| Control System | PLC Programming | Marketing Type | Ordinary Product |

| Port | Guangzhou |

Product Description

Product Description

Double position epoxy resin dispensing potting robot epoxy machine glue dispensing machine automatic spray glue machine

Features and Benefits:

1. The glue potting system are for AB component materials for metering, mixing and potting .

2. Precision metering and evenly mixing helps to avoid possible waste of glue.

3. Dispensing size and positioning keep consistently and high efficiency .

4. Good universality makes our machine suitable for applications of electric components , driver supply and others glue potting and dispensing needed products.

5. Easy to program and operate.

6.Fast metering & mixing and running speed keep potting with high efficiency.

7. Tally function, non-standard mode, tank level alert, filter mode, liquid display device, preventing back-flow device and other functional device.

2. Precision metering and evenly mixing helps to avoid possible waste of glue.

3. Dispensing size and positioning keep consistently and high efficiency .

4. Good universality makes our machine suitable for applications of electric components , driver supply and others glue potting and dispensing needed products.

5. Easy to program and operate.

6.Fast metering & mixing and running speed keep potting with high efficiency.

7. Tally function, non-standard mode, tank level alert, filter mode, liquid display device, preventing back-flow device and other functional device.

Applications:

1. Potting&Encapsulation &Casting:

electronics components , PCB board, Capacitor, power supply, transformer, ignition coil,reverse sensor, circuit board, electronic ballast , motor ,junction box ,switches, art mold ,aviation parts, aerospace parts and so on.

2. Dispensing&Dosing:

2. Dispensing&Dosing:

LED strip , led lamp , led bulb , aluminum,led screen , display module / medical parts,medical liquid

filling and so on ...

3. Bonding&doming:

filling and so on ...

3. Bonding&doming:

LCD screen ,LOCA bonding,ABS plastic / different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics ect .

Main Applications in electronics appliances

Transformer , capacitance , power module , regulating plate ,protection module , generator , pressure

package , solid relay ,fault indicator , Sensors , junction box , clutch , wave filter , water meter , battery cover , rectifier etc. ...

Main Applications in electronics appliances

Transformer , capacitance , power module , regulating plate ,protection module , generator , pressure

package , solid relay ,fault indicator , Sensors , junction box , clutch , wave filter , water meter , battery cover , rectifier etc. ...

Specification

Potting working area | 650mm×550mm×100mm |

Processing | dot , line , arc , circle |

Speed | 0---250mm/s |

Accuracy | ≤±0.2mm |

Mixing ratio | 1 :1 ---10:1 |

Out-glue speed | 0.5g/s -12g/s |

repeatability | ≤±2% |

program stock | 99pcs |

Viscosity | 0cps~50000cps |

Operation mode | Manual/auto/third party signal |

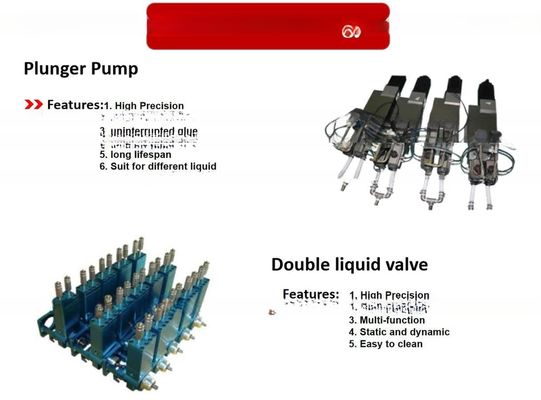

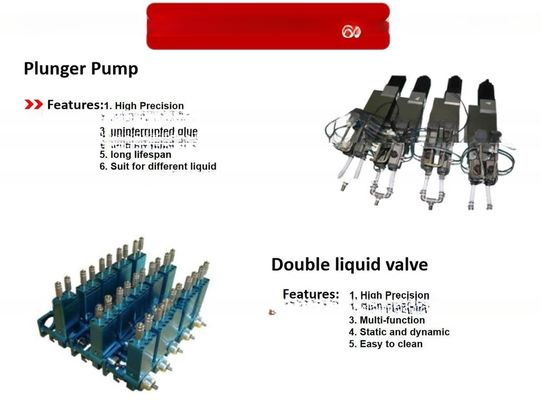

Ratio | PLC/Double cylinder plunger pump |

Flow control | Digital input |

Program method | Teaching programming |

Automatic controlling system | Touch screen / hand held tech box |

Mixing method | Dynamic/static |

Cleaning mode | Self-cleaning |

Tank | Stainless steel material barrel AB tank : 10L ,25L ,40L ,60L optional |

Vacuum degas(-0.1MPa),4L/s | |

Liquid sensor | |

Tank stirring | |

Power supply | 220V/50Hz/1500W(excluding heaters) |

Input air pressure | 0.4MPa—0.7MPa |

Outer dimension | 2092mm×1300mm X1157mm |

Appearance material | Stainless steel material + industrial aluminum profile |

Factory Overview

Recommended Products