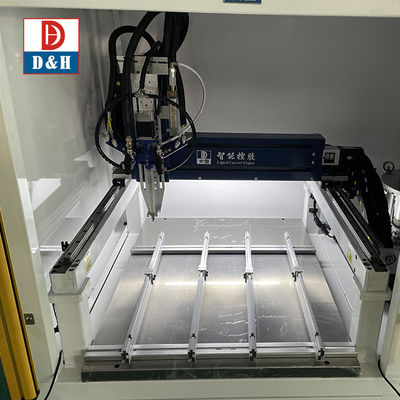

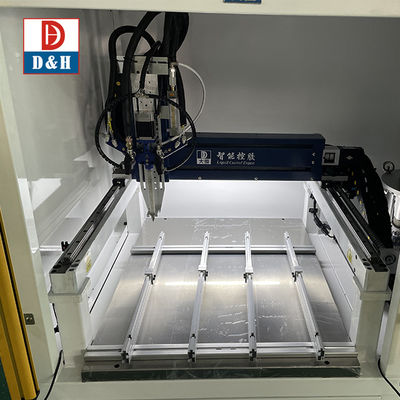

Optional Auto Cleaning 2K Dosing Machine for Polyurethane Resin and Epoxy Compound

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | New | Weight (KG) | 500 |

|---|---|---|---|

| Video Outgoing-inspection | Provided | Machinery Test Report | Provided |

| Marketing Type | Ordinary Product | Warranty Of Core Components | 1 Year |

| Core Components | PLC, Engine, Pump | Warranty | 1 Year |

| Applicable Industries | Manufacturing Plant, Any Industrial Products That Need Apply Adhesive, PU ,EPOXIES ,PU | Showroom Location | Turkey, Italy, Viet Nam, Philippines, Indonesia, India, Mexico, Russia, Sri Lanka, Malaysia |

| Key Words | Epoxy Resin Dispensing Machines With Vacuum Degas And Heating Options | Applicable Materials | PU,EPOXIES ,SILICONES |

| Tank Compacities | 10L,25L,60L Optional | Functions | Heating,vacuum ,stir |

| Mixing Mode | Dynamic Mixing | Auto Feeding | Available |

| Auto Cleanning | Optional | Mixing Ratio | 1:1-10:1 |

automatic polyer-resin ab PU epoxy silicones machine for potting electronic AB dispensing machine

Daheng fluids dispensing technology can handle 1- and 2-component polyurethanes, epoxies, acrylics, silicones, temperature,

humidity and UV curing materials.

They can be from low-to high-viscosity, filled or unfilled and even high abrasive material by potting , dispensing , bonding ,

dosing ,dropping ,spraying ,pouring and so on .

Applicable Material:

1K and 2-component polyurethanes, epoxies, acrylics, silicones, temperature, humidity and UV curing materials. Two component

potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU,

Ployerster, Polyurethane, UV materials and so on .

Introduction :

Working principle :

Tank system technology:

D&H Pump technology

Valve technology

ITEM | Parameter |

Mixing ratio | 1:1--10:1 adjustable |

Working range | 700*700*100mm |

Displacement speed | 250mm/s(speed) |

Out-glue speed | 1-12g/s per single pump |

Accuracy | ±2%(output volume)±2%(mixing) |

tolerance | ≤0.2mm |

Flow control | Digital input |

Program memory | 99pcs-999pcs |

Motion trail | Dot , line ,curve ,circle |

Automatic controlling system | Touch screen (to achieve program programming, modification, storage and so on |

Out-glue control system | AB glue back suction valve, achieve AB glue independent operation |

Programmatically | Tech programming/or computer systems (Micro software Windows 7,Windows10 optional) |

Mixing method | dynamic mixing |

Power supply | 220V/50Hz/1500W without heating |

Air source | 0.5-0.8Mpa |

Viscosity range | 50-20000cps |

Outer dimension | 1500L*1200W*1600H mm |

A tank | 10L 25L 40L stainless tank(optional) |

B tank | 10L 25L 40L stainless tank(optional) |

Others | AB tank 、A pump、AB pipeline heating function |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging | ||

Size | 150CM(L) * 110CM (W) * 170CM (D) | |

Weight | 550KGS | |

Packaging Details | The normal package is wooden box(Size: L*W*H). The wooden box will be fumigated. We will use pe film for packing or pack it according to customers special request. | |