● By air, for sample and small package, international express like DHL, UPS, EMS...

● By sea, for large package and quantity;

● Other ways as customer requested.

All Products

Two Component Liquid Mixing and Potting Machinery AB Epoxy Dispenser Gluing Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Type | Gluing Machine | Applicable Industries | Manufacturing Plant |

|---|---|---|---|

| Showroom Location | Turkey, Italy, Viet Nam, Indonesia, Russia, Thailand, Malaysia | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Warranty Of Core Components | 1 Year |

| Core Components | PLC, Pump | Condition | New |

| Application | PU,epoxies ,silicone | Packaging Type | Polywood Case |

| Packaging Material | Plastic, Polywood Case | Automatic Grade | Automatic |

| Driven Type | Electric | Voltage | 220V /380V |

| Weight | 500 KG | Warranty | 1 Year |

| Key Selling Points | High Productivity | Definition | Liquid Mixing And Potting Machinery AB Epoxy Dispenser |

| Feeding Way | Automatic Feeding | Function | Vacuum , Heat , Stir , Self-clean |

| Mixing Way | Dynamic /static Mixing | Tank Compacity | 10L,25L , 40L Or Customized |

| Precision | ±2% | Glue-out Precision | 0.5-12g/s |

| Speed | 0-300mm/s | Pump Precision | 0.2g/s |

| Control System | PLC Programming |

Product Description

Product Description

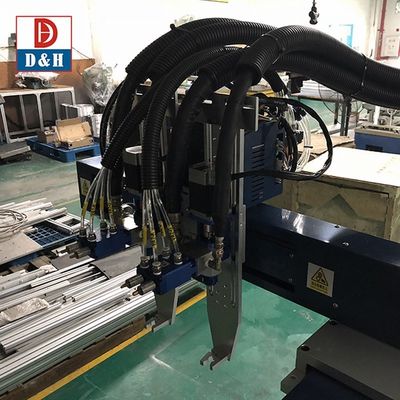

2 part dispensing machine control system mixer two component liquid mixing and potting machinery AB epoxy dispenser

Features and Benefits:

1. The glue potting system are for AB component materials for metering, mixing and potting .

2. Accurated metering and evenly mixing helps to avoid possible waste of glue.

3. Dispensing size and positioning keep consistently and fastly.

4. Good universality makes our machine suitable for applications of LED, electric and others glue potting and dispensing needed.

5. Easy to program and operate.

6.Fast metering & mixing and running speed keep potting with high efficiency.

7. Tally function, non-standard mode, tank level alert, filter mode, liquid display device, preventing backflow device and other functional device.

2. Accurated metering and evenly mixing helps to avoid possible waste of glue.

3. Dispensing size and positioning keep consistently and fastly.

4. Good universality makes our machine suitable for applications of LED, electric and others glue potting and dispensing needed.

5. Easy to program and operate.

6.Fast metering & mixing and running speed keep potting with high efficiency.

7. Tally function, non-standard mode, tank level alert, filter mode, liquid display device, preventing backflow device and other functional device.

Applications:

Reverse Sensor, Electronic Circuit Board, Electronic Ballast ,air Filters, LED products ,Electronic

components,Crafts,Ads modules, Capacitors, Power supply, Transformer, end cap for filter, solar junction box ,Power module,Ignition coil, Sensor, Photovoltaic module, Photovoltaic inverter. Etc

components,Crafts,Ads modules, Capacitors, Power supply, Transformer, end cap for filter, solar junction box ,Power module,Ignition coil, Sensor, Photovoltaic module, Photovoltaic inverter. Etc

Specification

Potting working area | 650mm×550mm×100mm |

Processing | dot , line , arc , circle |

Speed | 0---250mm/s |

Accuracy | ≤±0.2mm |

Mixing ratio | 1 :1 ---10:1 |

Out-glue speed | 0.5g/s -12g/s |

repeatability | ≤±2% |

program stock | 99pcs |

Viscosity | 0cps~50000cps |

Operation mode | Manual/auto/third party signal |

Ratio | PLC/Double cylinder plunger pump |

Flow control | Digital input |

Program method | Teaching programming |

Automatic controlling system | Touch screen / hand held tech box |

Mixing method | Dynamic/static |

Cleaning mode | Self-cleaning |

Tank | Stainless steel material barrel AB tank : 10L ,25L ,40L ,60L optional |

Vacuum degas(-0.1MPa),4L/s | |

Liquid sensor | |

Tank stirring | |

Power supply | 220V/50Hz/1500W(excluding heaters) |

Input air pressure | 0.4MPa—0.7MPa |

Outer dimension | 2092mm×1300mm X1157mm |

Appearance material | Stainless steel material + industrial aluminum profile |

Company Profile

About Company

■ About D&H

D&H is a company who has its own core tech and provides professional glue controlling solutions in the industry.In 2006 we developed the patent-“double cylinder plunger pump”,the glue dispensing machine with such a pump type was launched into the market successfully.This patent design becomes the heart of a new generation of metering device.The new design leads the liquid controlling device into a direction of high filling,high precision ,high crystallization,high output speed and production line.

Certifications

■ QUALIFICATION CERTIFICATE

We have more than 30 national patents, and are at the industry pioneer level in the core technologies of glue potting and dispensing

Sales Network & Customers

Exhibition

Packing & Delivery

■ Standard Wooden Case with Vacuum Package

FAQ

Q:Do you offer oversea service? A:We have overseas service center in some countries, we can support local service as per discussion. And we also can offer oversea service if customer required, engineer will offer face to face service. | ||||||||

Q:How dose your factory do regarding quality control? A:We assure 1 year warranty for the main part,also we offer spare part for back up. Please check with sales engineer in detail. | ||||||||

Q:What are your payment terms? A:Normally, 30% advance by T/T and balance paid off before delivery. | ||||||||

Q:Are you a factory or trading company ? A:We are a factory with SGS certified and more than 30 patents,and cooperate with different customers coverd about 50 countries for over 19 years. | ||||||||

Recommended Products